Pc 03 Error Code Mini Split: Troubleshooting And Solutions To Fix The Issue

The PC 03 error code on a mini split air conditioning system is a common problem that can cause frustration. Understanding how to troubleshoot and solve this error code is important for anyone relying on their mini split AC unit. By diagnosing and addressing the issue, you can restore the cool comfort of your mini split system.

In the world of mini split air conditioning systems, there’s an error code that often leaves users scratching their heads and feeling the heat. It’s the notorious PC 03 error code, and if you’ve ever encountered it, you know the frustration it brings.

But fear not, for within the realm of troubleshooting and problem-solving, lies the key to unlocking the cool comfort you seek. Imagine a scorching summer day when the temperature outside is mercilessly high.

You rush home, looking forward to the relief that your trusty mini split system provides. But as you eagerly adjust the settings, you’re greeted by a perplexing PC 03 error code glaring back at you. Your hopes plummet.

Understanding the ins and outs of this error code is essential for anyone who relies on their mini split AC unit. Whether you’re a tech-savvy DIY enthusiast or simply someone who wants to avoid costly repairs, having the knowledge to diagnose and solve the PC 03 error code can save you time, money, and endless discomfort. So, let’s dive into the fascinating world of troubleshooting and explore the solutions that will banish the PC 03 error code from your mini split system, restoring your cool oasis in no time.

- GREEN REFRIGERATION SOLUTION: ZeroR AC Refrigerant is a 100% natural hydrocarbon gas, offering a more eco-friendly alternative to traditional AC recharge like R134a. It helps reduce environmental impact while providing reliable cooling performance

- R134A READY INSTALLATION: Designed to fit R134a systems, ZeroR AC Refrigerant installs just like any standard refrigerant. The cans feature R134a-compatible threads, ensuring easy and seamless installation with your existing R 134a refrigerant can taps

- SMALLER CAN BIGGER IMPACT: Each can of our car AC refrigerant holds 6oz of refrigerant, but its performance is equivalent to 16oz of R134a. This makes it a highly efficient and cost-effective option, requiring less product while maintaining excellent performance

- BUILT FOR SAFE USAGE: ZeroR AC Car Refrigerant is rated with a class 2.1 rating, similar to newer refrigerants. When used in systems designed for refrigerants, it’s safe and poses no danger to users under normal operating conditions

- REGULATED FOR LEGAL SAFETY: ZeroR AC Recharge Can is approved for use in R134a systems only, in compliance with EPA regulations. It ensures proper functionality without the risk of mixing refrigerant types, providing peace of mind and legal safety

- IMPORTANT! – (1) Verify that you have an R134a system before purchasing! Do not rely on amazon data to help you, it is often wrong! Simply check your owners manual or look at the AC Service Sticker under the hood of your vehicle for “R134a”. (2) While low refrgierant is by far the most common issue which this kit does fix, there are other potential problems that a simple recharge will not address. Please know that used items are not eligible for a refund simply because “it didn’t work”. Your vehicle may have other issues. We are happy to provide tecnical support through all stages of your purchase and installation!

- AC CHARGE & DYE – Cans are primarily gas with a tiny amount of UV DYE. Dye is very common and will in no way affect the performance of your vehicle. This kit is not designed with enough UV DYE to perform a professional leak detection and repair process.

- 6oz (11.7 fl oz) Cans – Gas is a Hydrocarbon blend that is 100% natural, safe for the ozone and non global warming. Chemically compatible with R134a systems. Compressed gas is by standard measured by weight, not fluid ounces or system volume. This gas is light weight compared to others, but offers more “volume” than R134a due to it’s chemical makeup. Guaranteed that you will use no more cans than normal despite the lighter weight!

- SSV Cans & Tool – Self Sealing Valve allows for the storage of unused gas. Extra long 24″ hose and tap designed for SSV cans. Gauge reads R134a system pressures.

- Disclosures – Product is flammable like many other modern refrigerants. Observe all precautions on the product lablel when handling and storing. Follow all legal requirements when charging your system. Hydrocarbon blend refrigerant in 6oz SSV Cans for use in appliances, industrial applications and more. Used items are not eligible for

- Fit type: Vehicle Specific;Fit Type: vehicle specific

- Maximum cooling efficiency

- Brand New, OE replacement: UAC branded Oil;Fit Type: vehicle specific

- Brand New, OE replacement: UAC branded Oil

- One A/C Pro Auto AC Recharge Gauge and Hose Dispenser, ACP410-4

- Extra large easy-to-read gauge for accurate charging

- 24″ AC charging hose is long enough to reach difficult ports

- Push-on quick-connect coupler lets you easily connect the refrigerant hose

- Trigger dispenser offers easy use for effortless recharging

- 【Superior Quality】: This refrigerant charge hose is made from high-quality nylon, offering superior pressure resistance and durability. The brass connectors enhance the overall strength and protect against leakage, ensuring reliable performance in demanding conditions.

- 【Efficient Charging】: This kit is designed for efficient and precise refrigerant charging. It features a self-sealing valve for easy connection and minimal waste. The system ensures an accurate charge, helping to maintain optimal air conditioning performance.

- 【Pressure Gauge】: Equipped with a clear, easy-to-read pressure gauge, this hose kit enables users to monitor refrigerant pressure during the charging process. It helps ensure that the correct amount of refrigerant is charged, protecting the A/C system from damage.

- 【Easy Operation】: The hose kit features simple installation and operation. Just connect the self-sealing valve to the refrigerant can, attach the hose to the A/C service port, and use the dispensing valve to control refrigerant flow. The whole process is quick and effortless.

- 【Wide Applicability】: This refrigerant charge hose kit is compatible with most vehicles and applications that use R134A refrigerant, including cars, trucks, and household A/C systems. It can be used for refrigerant tanks with 1/2-inch threaded connections.

- Innovative Leak Detection: Equipped with UV dye for quick and easy identification of leaks in your A/C system

- Accurate Digital Gauge: Provides precise pressure readings for a more controlled and comes with Smart Clips to ensure exact recharge

- Effortless Connection: User-friendly attachment process with Turn-N-Push dispenser prevents accidental discharge and loss of refrigerant

- Enhanced Performance: Features a Safe-Seal formula that ensures long-lasting and reliable cooling

- Comprehensive Solution: All-in-one 18 oz can designed for both professional and DIY use with reusable tooling with 12 inch braided recharge hose

- Upgraded version of WJL-6000. Traditional corona sensor with updated analogue circuit, fast triggers on R11, R22, R134A, R404a, R410A and all halogenated refrigerants including HFCs, CFCs,HCFCs and blends.

- 6s preheating time, instantaneous response; 6 adjustable sensitivity, sensitivity of 0.21oz/yr.

- A flexible probe around 8.26 inches allows detections in difficult and hard-to-reach areas.

- Direct status indication with audible & visual leakage alarm indicators and dual colour battery indicators. Battery by 4 AAA batteries (Not included)

- 24/7 US Technician Support via Email and Phone.

- WIDE COMPATIBILITY —- A/C can tap guage hose recharge for R134A R12 or R22 refrigerant refrigerant to vehicle or home air-conditioning, with highly working performance.

- PREMIUM QUALITY —- R134A puncture type can tap, R134A low side quick are made of aluminium alloy, for high heat resistance durability and safety.

- EASY INSTALLATION —- R134A gauge recharge hose has 90 degree Push & Lock coupler with auto shut off. Easy and convenient to use. Come with gauge for easily viewing during use and getting a correct charge.

- DIMENSION —- 1/2” ACME female x 1/4” SAE male can tap opener, 13mm R134A low pressure quick coupler, thread: female low side R134a 13 mm quick coupler x male 1/4” SAE FL.

- PACKAGE INCLUDES —- With 1/2” ACME puncture frezon can tap, recharge Hose with gauge and R134A low side quick coupler. Note: If the pressure gauge needle is not on 0psi, open the cover of the gauge and adjust the knob on the gauge before using.

- 【High-Quality Material】:This R134A charging hose for automotive air conditioning with pressure gauge is made of high-quality rubber material, corrosion resistance, and durability, ensuring high heat resistance built-in safety valve to prevent accidental discharge of refrigerant, reliable performance, and long-term use.

- 【Wide Compatibility】:Air conditioning charging hose with gauge is available with a 1/2 ” can tap valve and R134A low side quick coupler, fit for 1/2 thread in the United States and Europe for adding R134A refrigerant to car or home air conditioning.

- 【Easy to Use】:Car air conditioning charging kit with 90-degree push lock coupling design, easy to connect and disconnect, easy to use, with pressure gauge, easy to monitor the low-pressure side pressure of car air conditioning during use, to ensure and correct charging. Note: The reading is correct only when the AC compressor is working.

- 【Specification】:The total length of the R134A AC refrigerant charge hose has an overall length of 19.29 inches and a hose length of 17.32 inches. The pressure gauge is rated to a maximum of 100psi, the hose is rated to a maximum of 600psi working pressure, and the burst pressure is 3,000 psi. The T-knob has a needle tip inside to help Pierce the refrigerant bottle quickly and easily.

- 【What You Get】:You will receive 1 R134A refrigerant charging hose with a pressure gauge, it is a simple and useful tool for measuring AC suction service port dynamic pressure and Freon charging.

- Meets OEM performance specifications

- High performance synthetic PAG for R134a systems provides excellent resistance to moisture

- Anti-Wear Agents and Friction Modifiers enhance compressor wear rates which extend compressor life

- Anti-Oxidants protect system against formation of sludge which can shorten compressor life and reduce system efficiency

- Contains UV Dye for Leak Detection

Overview of PC 03 Error Code in Mini Split Systems

Explanation of error codes in mini split systems

Before diving into the specifics of the PC 03 error code, it’s important to understand the role of error codes in mini split systems. Error codes serve as diagnostic tools that indicate a problem or malfunction within the system. When an error occurs, the mini split unit detects the issue and displays a corresponding code on the control panel.

These error codes provide valuable information to both users and technicians, helping to identify the underlying cause of the problem. By deciphering these codes, you can effectively troubleshoot and resolve issues, ensuring optimal performance and longevity of your mini split system.

Introduction to PC 03 error code

Now, let’s focus on the PC 03 error code specifically. When this code appears on your mini split display, it signifies a problem related to the system’s refrigerant levels, temperature sensors, airflow, or electrical components. Each of these issues requires careful evaluation and troubleshooting to pinpoint the exact cause and implement the necessary solutions.

II. Causes of PC 03 Error Code

A. Insufficient refrigerant levels

1. Low refrigerant charge due to leaks

One of the common causes of the PC 03 error code is insufficient refrigerant levels. This can occur when there are leaks in the refrigerant lines or connections. Over time, these leaks can lead to a decrease in refrigerant charge, resulting in poor cooling performance and the appearance of the PC 03 error code.

To address this issue, it’s important to identify the leak points and repair them. Once the leaks are sealed, the refrigerant can be recharged to the appropriate levels, resolving the PC 03 error code and restoring the system’s functionality.

2. Improper installation or evacuation process

Another factor that can contribute to low refrigerant charge and the subsequent PC 03 error code is improper installation or evacuation processes. If the system was not installed correctly or if the evacuation process was not performed thoroughly, it can result in air or moisture in the refrigerant lines, leading to reduced refrigerant levels.

In such cases, it’s crucial to enlist the help of a professional technician to properly evacuate the system and ensure the correct installation procedures are followed to prevent future issues and the recurrence of the PC 03 error code.

3. System aging and wear and tear

Over time, mini split systems may experience wear and tear, which can result in refrigerant leaks and diminished refrigerant levels. As the system ages, it becomes more susceptible to corrosion, physical damage, and deterioration of seals and connections.

Regular maintenance and inspections can help identify and address these issues before they escalate, minimizing the chances of encountering the PC 03 error code and prolonging the lifespan of your mini split system.

B. Faulty temperature sensors

1. Malfunctioning outdoor temperature sensor

The outdoor temperature sensor plays a critical role in regulating the operation of the mini split system. It continuously monitors the ambient temperature and sends signals to the control board, enabling the system to adjust its performance accordingly.

If the outdoor temperature sensor malfunctions or provides inaccurate readings, it can trigger the PC 03 error code. In such cases, the sensor may need to be replaced to restore proper functionality and eliminate the error.

2. Faulty indoor temperature sensor

Similar to the outdoor temperature sensor, the indoor temperature sensor is responsible for monitoring the temperature within the room or space being cooled. It relays this information to the control board, allowing the mini split system to adjust its cooling output.

If the indoor temperature sensor is faulty or damaged, it can result in erroneous temperature readings and the subsequent appearance of the PC 03 error code. Replacing the faulty sensor can rectify the issue and ensure accurate temperature control.

C. Airflow issues

1. Blocked or dirty air filters

Air filters in mini split systems play a vital role in maintaining indoor air quality and ensuring efficient operation. However, over time, these filters can become clogged with dust, debris, and other particulate matter, impeding the flow of air.

When the airflow is restricted, the system may struggle to cool the space effectively, leading to the PC 03 error code. Regular cleaning or replacement of the air filters is essential to maintain proper airflow and prevent the recurrence of this error.

2. Restricted air intake or outlet

In addition to clean air filters, sufficient airflow also depends on unobstructed air intake and outlet vents. If these vents are blocked or obstructed by furniture, curtains, or other objects, the system may experience airflow issues, resulting in poor cooling performance and the appearance of error codes.

Ensuring that the air intake and outlet vents are free from obstructions can significantly improve airflow and mitigate the chances of encountering the PC 03 error code.

3. Malfunctioning fan motor or blades

The fan motor and blades in a mini split system are responsible for circulating the air and enhancing heat exchange. If the fan motor malfunctions or the blades are damaged or misaligned, it can disrupt the airflow and impede the system’s cooling capabilities.

If airflow issues persist despite clean filters and unobstructed vents, it may be necessary to inspect and repair or replace the fan motor and blades to resolve the PC 03 error code.

D. Electrical problems

1. Faulty or damaged wiring

Electrical issues can also contribute to the appearance of the PC 03 error code. Faulty or damaged wiring can result in poor electrical connections or short circuits, disrupting the communication between different components of the mini split system.

Thoroughly inspecting the wiring for any signs of damage and ensuring secure connections can address these electrical issues and eliminate the error code.

2. Loose connections or poor electrical supply

In addition to damaged wiring, loose connections or poor electrical supply can also cause the PC 03 error code. Loose connections can lead to intermittent power interruptions or inadequate voltage delivery to the system, triggering error codes.

Checking and tightening all electrical connections, as well as ensuring a stable and sufficient electrical supply to the mini split system, can rectify these issues and prevent the recurrence of the PC 03 error code.

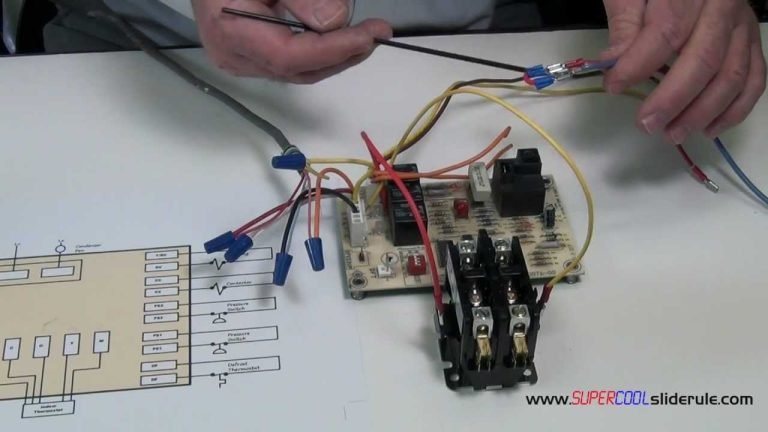

3. Defective control board or circuit components

If all other potential causes have been ruled out, a defective control board or malfunctioning circuit components may be responsible for the PC 03 error code. These issues require professional assistance to diagnose and repair.

A qualified technician will be able to assess the control board and circuitry to identify any faults or defects. Depending on the severity of the problem, the control board or specific components may need to be replaced to resolve the error code.

III. Diagnostic Procedures for PC 03 Error Code

A. Identifying PC 03 error code on the mini split display

When the PC 03 error code appears on your mini split display, it’s essential to take note of the code and any accompanying symbols or indicators. This information will aid in troubleshooting and guide you towards the specific cause of the error.

B. Checking refrigerant levels and detecting leaks

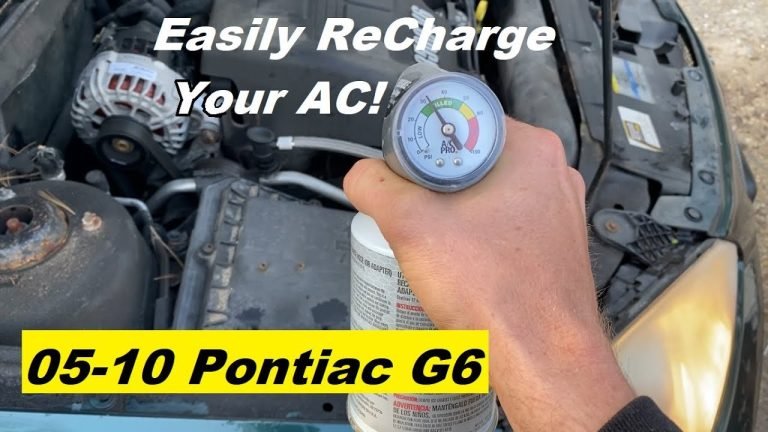

1. Using pressure gauges to measure refrigerant pressure

One of the first steps in diagnosing the PC 03 error code is checking the refrigerant levels in the system. This can be done using pressure gauges to measure the high and low side pressures.

If the refrigerant pressure is below the manufacturer’s recommended range, it indicates a low refrigerant charge, which may be due to leaks or other issues.

2. Inspecting visible refrigerant lines and connections

Visually inspecting the refrigerant lines and connections can help identify any visible signs of leaks or damage. Look for oil stains, frost accumulation, or hissing sounds, which may indicate refrigerant leaks.

If leaks are detected, it’s crucial to address them promptly to prevent further refrigerant loss and resolve the PC 03 error code.

3. Conducting electronic leak detection tests

In some cases, refrigerant leaks may not be readily visible. In such instances, electronic leak detection tools can be used to pinpoint the exact location of the leaks.

By passing the electronic leak detector along the refrigerant lines and connections, any leaks can be detected, allowing for targeted repairs and recharging of refrigerant.

C. Testing temperature sensors

1. Using a multimeter to measure resistance values

Temperature sensors can be tested using a multimeter to measure their resistance values. Each sensor has a specific resistance range, and deviations from this range can indicate a faulty sensor.

Consult the manufacturer’s specifications for the correct resistance values and compare them to the readings obtained from the sensors. If there is a significant difference, it may be necessary to replace the faulty sensor.

2. Ensuring proper placement and positioning of sensors

Temperature sensors must be properly positioned and placed to provide accurate temperature readings. Incorrect placement or misalignment can lead to erroneous signals being sent to the control board, triggering error codes like PC 03.

Check that the sensors are securely mounted, correctly positioned, and undamaged to ensure their proper functioning.

D. Assessing airflow issues

1. Inspecting and cleaning air filters

If airflow issues are suspected, start by inspecting and cleaning the air filters. Remove any accumulated dirt, dust, or debris by gently washing the filters or using a vacuum cleaner.

Clean air filters contribute to improved airflow and prevent the recurrence of the PC 03 error code.

2. Clearing blockages in air intake or outlet

Ensure that the air intake and outlet vents are free from any obstructions. Remove any objects or debris that may be blocking the vents, hindering the airflow.

Improving the airflow by clearing blockages can help resolve the PC 03 error code.

3. Verifying proper operation of fan motor

Inspect the fan motor and blades to ensure they are functioning correctly. If the motor is not running or the blades are damaged, it can result in inadequate airflow and the appearance of error codes.

Repair or replace the fan motor and blades as necessary to restore proper airflow and eliminate the PC 03 error code.

E. Evaluating electrical components

1. Inspecting wiring for damage or loose connections

Thoroughly inspect the wiring connecting various components of the mini split system. Look for any signs of damage, frayed wires, or loose connections.

Repair or replace damaged wiring and ensure all connections are secure to resolve any electrical issues that may be causing the PC 03 error code.

2. Testing electrical supply and voltage levels

Ensure that the electrical supply to the mini split system is stable and within the specified voltage range. Fluctuations or inadequate voltage delivery can trigger error codes like PC 03.

Consult a qualified electrician to assess the electrical supply and make any necessary adjustments or repairs to prevent the recurrence of the error code.

3. Diagnosing control board and circuitry problems

If all other diagnostic procedures have been conducted and the PC 03 error code persists, it may indicate a problem with the control board or other circuit components.

Consult a professional technician who can perform comprehensive diagnostics and repair or replace any faulty control board or circuitry to resolve the error code.

IV. Troubleshooting and Resolving PC 03 Error Code

A. Adding refrigerant and repairing leaks

1. Identifying leak points and repairing them

If low refrigerant levels are the cause of the PC 03 error code, it’s crucial to identify the leak points and repair them to prevent further refrigerant loss.

Once the leaks have been addressed, the system can be recharged with the appropriate refrigerant to restore optimal cooling performance.

2. Recharging the system with the appropriate refrigerant

After repairing any leaks, it’s important to recharge the system with the appropriate refrigerant to bring the levels back to the manufacturer’s recommended specifications.

Consult the unit’s user manual or seek professional assistance to ensure the correct refrigerant type and amount are used to avoid further issues and the recurrence of the PC 03 error code.

B. Replacing faulty temperature sensors

1. Removing and replacing outdoor temperature sensor

If the outdoor temperature sensor is found to be faulty, it can be replaced by carefully disconnecting it from the control board and installing a new sensor in its place.

Ensure the new sensor is compatible with your mini split system and follow the manufacturer’s instructions for proper installation.

2. Replacing indoor temperature sensor

Similarly, if the indoor temperature sensor is determined to be the cause of the PC 03 error code, it can be replaced by disconnecting the faulty sensor and installing a new one.

Refer to the manufacturer’s guidelines for the correct replacement sensor and installation procedure.

C. Correcting airflow issues

1. Cleaning or replacing air filters

If dirty or clogged air filters are responsible for the PC 03 error code, they can be cleaned by gently washing or vacuuming them. In some cases, replacement may be necessary if the filters are damaged or cannot be adequately cleaned.

Regular filter maintenance, either through cleaning or replacement, is essential to ensure proper airflow and prevent the recurrence of the error code.

2. Clearing obstructions in air intake or outlet

By removing any obstructions from the air intake or outlet vents, you can restore proper airflow and eliminate the PC 03 error code. Ensure that furniture, curtains, or other objects are not blocking the vents.

3. Repairing or replacing fan motor or blades

If the fan motor is malfunctioning or the blades are damaged, they may need to be repaired or replaced to restore proper airflow and cooling performance.

Consult a professional technician to assess the fan motor and blades and carry out the necessary repairs or replacements.

D. Fixing electrical problems

1. Repairing or replacing damaged wiring

If faulty or damaged wiring is the cause of the PC 03 error code, it must be repaired or replaced. Ensure that all wiring is in good condition and securely connected.

Seek the assistance of a qualified electrician to carry out any necessary repairs to the wiring system.

2. Ensuring secure and proper connections

Check all electrical connections within the mini split system to ensure they are secure and properly seated. Loose connections can result in error codes and poor system performance.

Tighten any loose connections and ensure they are properly fastened to resolve electrical issues contributing to the PC 03 error code.

3. Replacing defective control board or circuit components

If all other troubleshooting steps have been exhausted and the PC 03 error code persists, it may indicate a problem with the control board or other circuit components.

A professional technician should be consulted to diagnose and replace any defective control board or circuitry, ensuring the proper functioning of the mini split system.

V. Preventive Maintenance to Avoid PC 03 Error Code

A. Regular filter cleaning or replacement

To prevent airflow issues and the subsequent appearance of error codes like PC 03, it’s crucial to perform regular maintenance on the air filters of your mini split system.

Clean or replace the filters according to the manufacturer’s recommendations or as necessary, depending on environmental conditions and usage.

B. Annual inspection for refrigerant leaks

Refrigerant leaks are a common cause of the PC 03 error code. To prevent these leaks and maintain optimal refrigerant levels, it’s recommended to schedule an annual inspection of your mini split system.

A professional technician can perform leak detection tests, check the refrigerant lines for any signs of damage, and ensure the integrity of the system.

C. Scheduled calibration and testing of temperature sensors

Temperature sensors play a crucial role in the proper functioning of your mini split system. To ensure their accuracy and reliability, it’s important to schedule regular calibration and testing.

A professional technician can assess the sensors, adjust their calibration if necessary, and verify their proper operation.

D. Cleaning and maintenance of fan motor and blades

Regular cleaning and maintenance of the fan motor and blades can help prevent issues with airflow and cooling performance.

Remove any accumulated dirt or debris from the fan motor and blades, ensuring they are in good condition and functioning properly.

E. Periodic inspection of wiring and electrical components

Electrical problems can lead to error codes like PC 03 in mini split systems. To avoid these issues, it’s advisable to periodically inspect the wiring and electrical components of your system.

Look for any signs of damage or wear and tear, and ensure all connections are secure and properly seated. Consult a professional if any issues are detected.

VI. Conclusion

The PC 03 error code in mini split systems can be frustrating, but armed with the knowledge of its causes and solutions, you can troubleshoot and resolve the issue with confidence.

By addressing problems related to refrigerant levels, temperature sensors, airflow, and electrical components, you can restore the functionality and performance of your mini split system, ensuring cool comfort in any season.

In addition, practicing preventive maintenance and regular inspections will help you avoid future encounters with the PC 03 error code, prolonging the lifespan and efficiency of your mini split system.

What is a P1(PC 01 4th Gen) – P4 Error (PC 04 4th Gen) Code? – MRCOOL DIY Ductless Mini Split

Frequently Asked Questions (FAQ)

What does the PC 03 error code on my mini-split indicate?

How can I fix the PC 03 error code on my mini-split?

Can a PC 03 error code be caused by a faulty remote control?

Do I need to call a technician for a PC 03 error code on my mini-split?

Is the PC 03 error code common in mini-split systems?

Final Summary: Diagnosis and Prevention of the PC 03 Error Code in Mini Split Systems

In conclusion, the PC 03 error code in mini split systems is an indication of a problem related to refrigerant levels, temperature sensors, airflow, or electrical components. Insufficient refrigerant levels can be caused by leaks, improper installation or evacuation processes, or system aging and wear and tear.

Faulty temperature sensors can result in inaccurate readings and trigger the error code. Airflow issues can arise from blocked or dirty air filters, restricted air intake or outlet vents, or malfunctioning fan motor or blades.

Electrical problems, such as faulty or damaged wiring, loose connections, or poor electrical supply, can also contribute to the appearance of the PC 03 error code. To diagnose and resolve the PC 03 error code, various diagnostic procedures can be used, including measuring refrigerant pressure, inspecting visible refrigerant lines and connections, testing temperature sensors, assessing airflow issues, and evaluating electrical components. Based on the diagnosis, appropriate troubleshooting steps can be taken, such as repairing leaks, recharging the system with refrigerant, replacing faulty temperature sensors, correcting airflow issues by cleaning or replacing air filters and clearing obstructions, and fixing electrical problems by repairing or replacing damaged wiring and ensuring secure connections.

In some cases, a defective control board or malfunctioning circuit components may need to be replaced. To prevent the recurrence of the PC 03 error code, regular preventive maintenance should be practiced, including cleaning or replacing air filters, scheduling annual inspections for refrigerant leaks, calibrating and testing temperature sensors, cleaning and maintaining fan motor and blades, and periodically inspecting wiring and electrical components. By following these preventive measures, users can avoid encountering the PC 03 error code and ensure the optimal performance and longevity of their mini split systems.